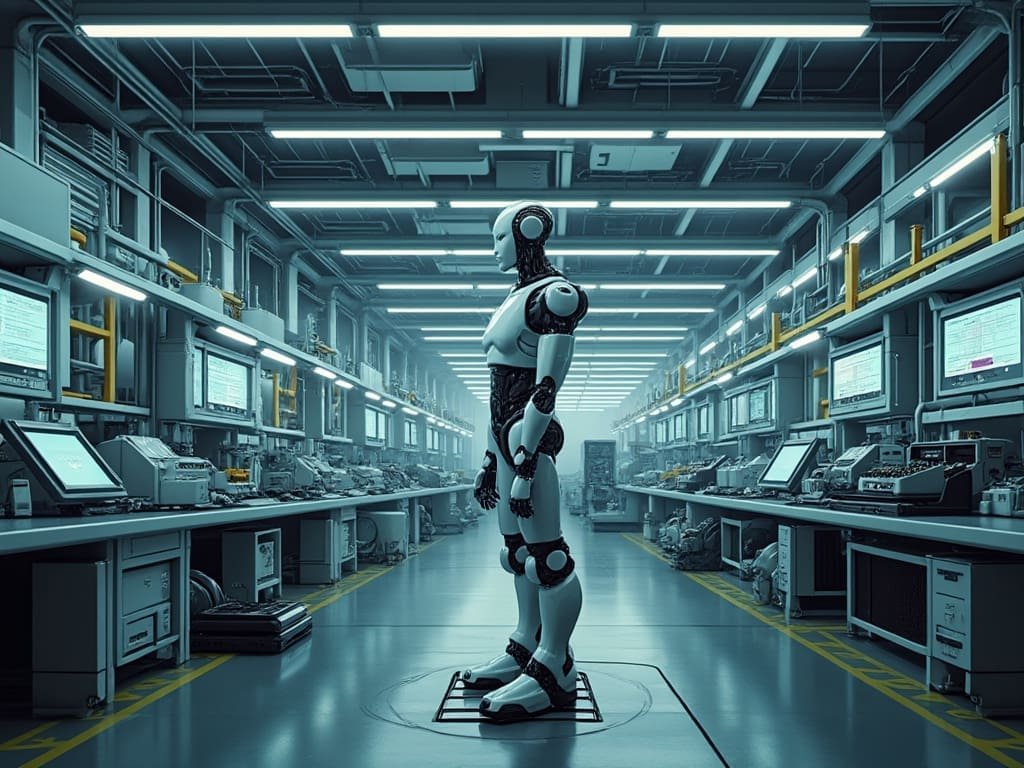

Physical AI is rapidly transforming global industries and marking the beginning of a powerful new industrial era. This next-generation technology blends artificial intelligence with advanced physical systems to help machines perceive, understand, reason, and act in real-world environments. From autonomous robots to intelligent cameras and self-driving vehicles, physical AI enables machines to make informed decisions and adapt to unpredictable surroundings.

The Evolution of Automation and Rise of Autonomous Intelligence

The journey toward physical AI can be understood through three major waves of automation.

The first wave, rule-based automation, began in the 1960s and powered traditional robots designed for repetitive, high-volume tasks such as welding in car factories. These machines delivered efficiency but lacked flexibility.

The second wave, training-based automation, is emerging today. Robots in this phase learn through AI and machine learning simulations. They can handle mid-volume tasks, adapt faster, and require shorter deployment timelines. This marks a shift toward smarter, more responsive machines.

The most advanced wave is context-based automation. These robots integrate vision systems, tactile sensors, and powerful AI foundation models. They can recognize their surroundings, interpret unfamiliar tasks, and make autonomous decisions with human-like intuition. This evolution signals a clear transition from simple automation to full autonomy.

How Physical AI Solves Real-World Industrial Challenges

Physical AI arrives at a time when industries worldwide are grappling with supply chain vulnerabilities, rising operational expenses, labour shortages, and demand for personalized production. Intelligent robotics bridges the digital and physical worlds to deliver agility and resilience.

Early adopters are already seeing major gains. Amazon operates over a million robots across its fulfillment centers. Physical AI has boosted overall efficiency by 25% and improved mobile robot travel efficiency by 10%. Delivery times have accelerated, and the company has created 30% more skilled jobs at specialized test sites.

Electronics giant Foxconn has also benefited. By using AI-driven digital twins to automate complex tasks like precision screw tightening, the company has reduced development time by 40%, increased cycle speeds by up to 30%, and lowered error rates by 25%. These results show the transformative impact of physical AI on large-scale manufacturing.

Why Physical AI Matters for the Future

Physical AI turns machines into intelligent systems capable of learning and adapting independently. High-fidelity physics-based simulations allow robots to practice tasks safely and efficiently before entering the real world. This capability unlocks true autonomy across industries.

In robotics, physical AI powers warehouse navigation, adaptive robotic arms, and even advanced surgical assistants. In autonomous vehicles, it processes real-time sensor data to interpret complex, unpredictable environments. It also supports “smart spaces” in factories by integrating sensor networks that enhance logistics, safety, and workflow.

Ultimately, physical AI fuses digital intelligence with physical capability, creating machines that think, learn, and collaborate alongside humans. It is poised to become a core driver of the fourth industrial revolution.